- High Precision: Capable of accurately measuring tension or weight, ensuring data reliability.

- Rapid Response: Provides real-time feedback on tension changes, suitable for dynamic monitoring.

- Durability: Typically made from high-strength materials to withstand harsh environments.

- Variety: Different types can be chosen based on application needs (e.g., piezoelectric, strain gauge).

- Easy Integration: Convenient to connect with other devices or systems, suitable for automation applications.

- Safety: Offers overload protection to prevent equipment damage and safety incidents.

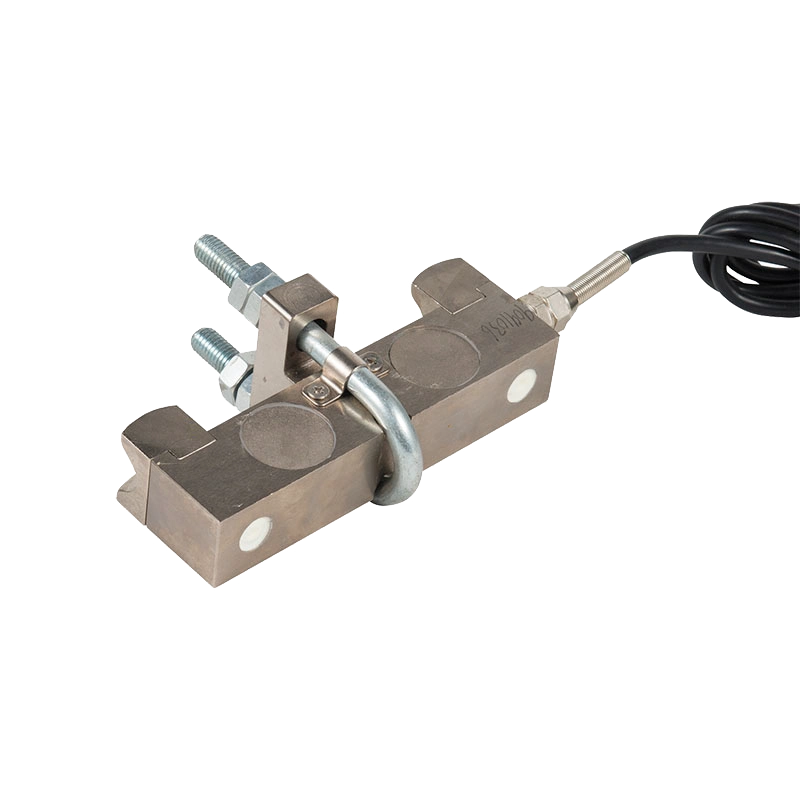

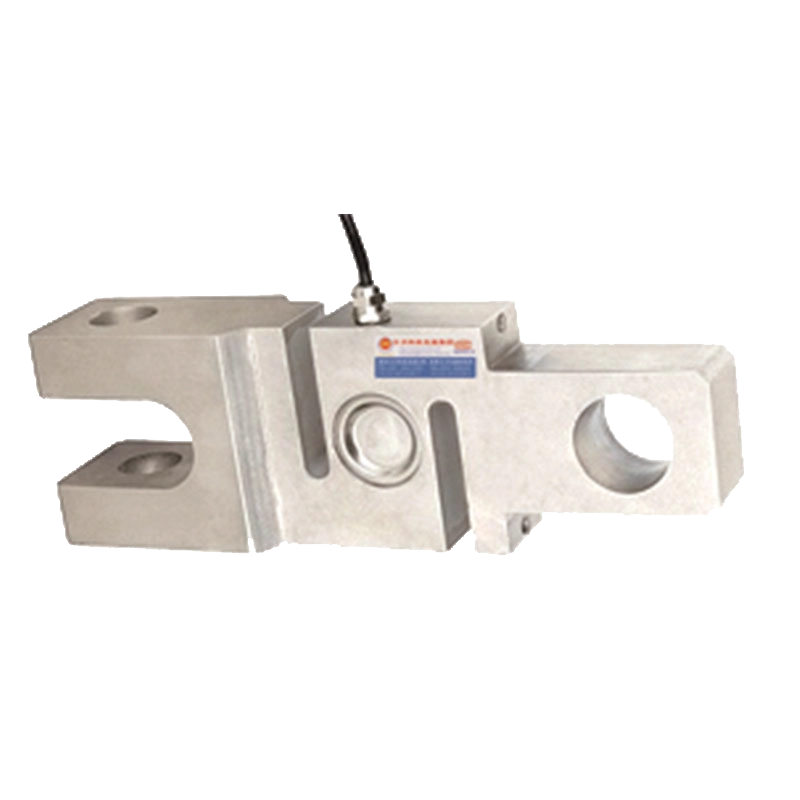

1t – 110146A1t SM46A Pull Force Sensor

Product Description

The SM46A series tension sensors are designed to measure a wide range of static or dynamic tension applications. The SM46A series tension sensor is the best choice, especially when the harsh working environment on the site has high requirements for durability and technical reliability. This product can be designed according to common standards and non-standard custom design to meet the needs of various applications, such as: a variety of hook scales, lifting overload protection equipment.

If the mechanical tension sensor has special shape or interface requirements, our company can be specially designed and customized according to the requirements. The SM46A series of tension sensors are equipped with a standard current interface, CAN bus interface or wireless sensor network interface.

1. Tension measurement range from 1t to 25t optional;

2. High reliability design;

3. A variety of measurement signal output schemes: analog standard signal output, digital bus output, wireless sensor network output;

4. Accuracy grade 0.3;

5. The measuring body material is made of high performance alloy steel or stainless steel;

6. Measure body safe overload range 200% F·S;

7. Industrial design, protection level IP67;

8. Operating temperature range from -40℃ to +85℃

9. ESD electrostatic protection, EFT transient suppression; SPD surge protection;

10. Power supply and signal reverse polarity protection; External steel connector shield.

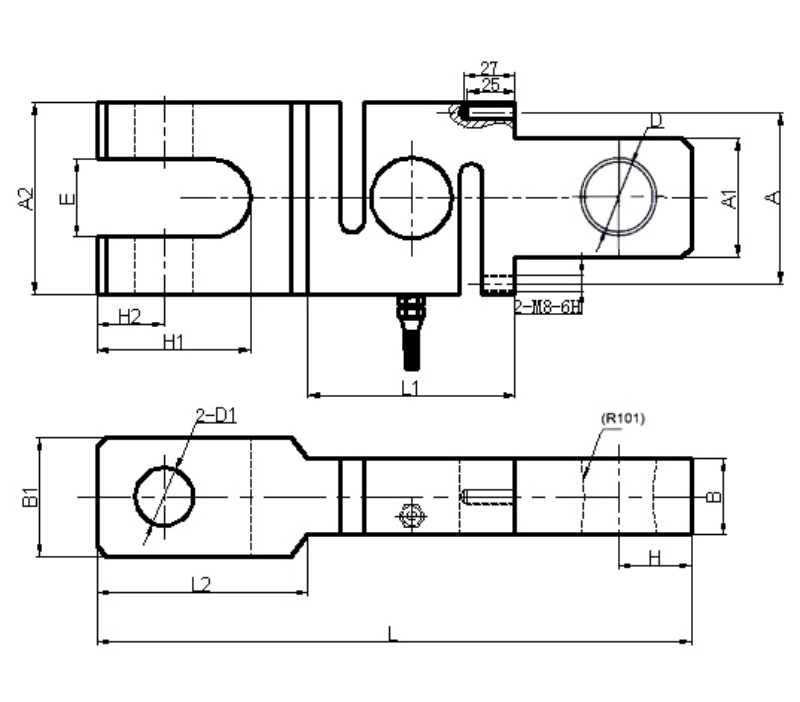

SM46A Pull Force Sensor Dimensions(In mm. 1mm=0.03937 inches)

| CAP./SIZE(量程/尺寸) | A | A1 | A2 | B | B1 | D | D1 | H | H1 | H2 | E | L | L1 | L2 |

| kg/mm | ||||||||||||||

| 2~7.5 | 89 | 62 | 100 | 40 | 62 | 36 | 30 | 38 | 80 | 35 | 40.4 | 310 | 108 | 110 |

| 10~15 | 104 | 80 | 126 | 50 | 68 | 39.5 | 35 | 36 | 98 | 37 | 50.8 | 324.5 | 93.5 | 136 |

| Ib/inches(conversion of above dimensions)由以上尺寸转换 | ||||||||||||||

| 4409.25~16534.67 | 35.04 | 24.41 | 39.37 | 15.75 | 24.41 | 14.17 | 11.81 | 14.96 | 31.50 | 13.78 | 15.91 | 122.05 | 42.52 | 43.30711 |

| 22046.23~33069.34 | 40.94 | 31.50 | 49.61 | 19.69 | 26.77 | 15.55 | 13.78 | 14.17 | 38.58 | 14.57 | 20.00 | 127.76 | 36.81 | 53.543336 |

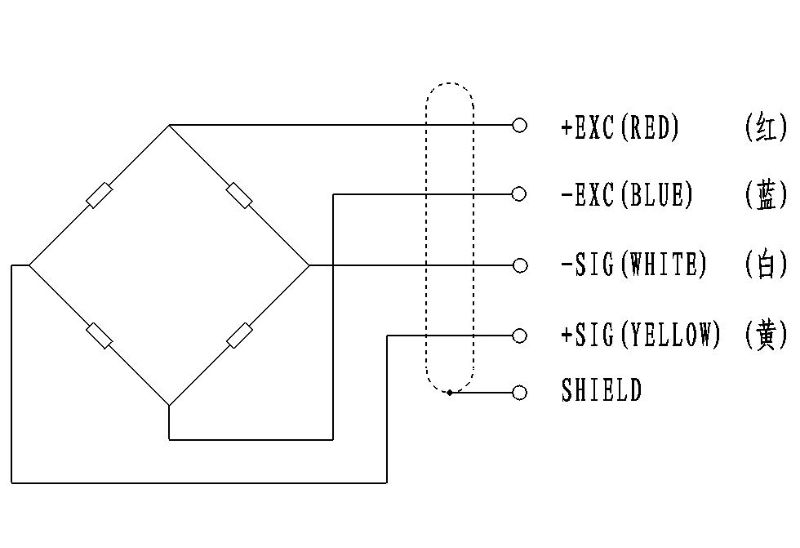

Circuit Diagram 电路图:

Red: +input

Blue: -input

White: +output

Yellow: -output

SM46A Pull Force Sensor Specification :

| Type | Technical parameters |

| Nominal load range | 2~15t |

| Power supply | 10~12 VDC |

| Drawing current | <100 mA |

| Zero balance | 1.0±% of rated output |

| Analog output | 2.0±0.015mV/V |

| Input resistance(Rlc) | 380±10Ω(ohms) |

| Output resistance(Ro) | 350±5Ω(ohms) |

| Insulation resistance | ≥5000 MΩ(Mege-Ohms) |

| Class precision | 0.3%FS |

| Effect of temperature | 0.3%FS/10℃ |

| Operating temperature | -40~+85℃ |

| Safe Load Limit | 200% FS |

| Safety margin against yielding | 300% FS |

| Safety margin against breakage | 500% FS |

| Material material | High performance alloy steel or (chromium ratio>15% stainless steel) |

| Protection type | IP67/IP68 |

SM46A Pull Force Sensor Application

Lifting and handling

Lifting equipment: real-time monitoring of tension in equipment such as cranes and hoists to ensure safe operation and prevent overload.

Hoists: used to monitor the tension during material lifting to ensure that the material rises or falls stably and safely.

Manufacturing

Production line monitoring: in the automated production process, monitor and control the tension of materials to ensure product quality and consistency.

Quality inspection: used to perform tension tests on finished products to ensure that they meet design standards and safety specifications.

Civil engineering

Structural monitoring: in structures such as buildings, bridges and tunnels, monitor tension to evaluate structural safety and prevent potential engineering accidents.

Foundation and soil testing: used to detect the reaction of soil after tension is applied and evaluate the bearing capacity of the foundation.

Scientific research and experiments

Material testing: in material science, tensile tests are performed to analyze the strength, ductility and other mechanical properties of materials.

Mechanical research: widely used in experimental research in fields such as engineering, physics and biomechanics.

Aerospace

Aircraft testing: Ensure the safety and stability of components under extreme conditions during tensile testing of aircraft.

Sports and fitness

Sports equipment: Monitor the tensile force on fitness equipment to help users optimize training results and prevent injuries.

Power and energy

Wind turbines: Monitor the tensile force of wind turbines to ensure their safety under high wind speed conditions.

Get In Touch With Us !

Related Products

Related Productspartner

partner

download

download