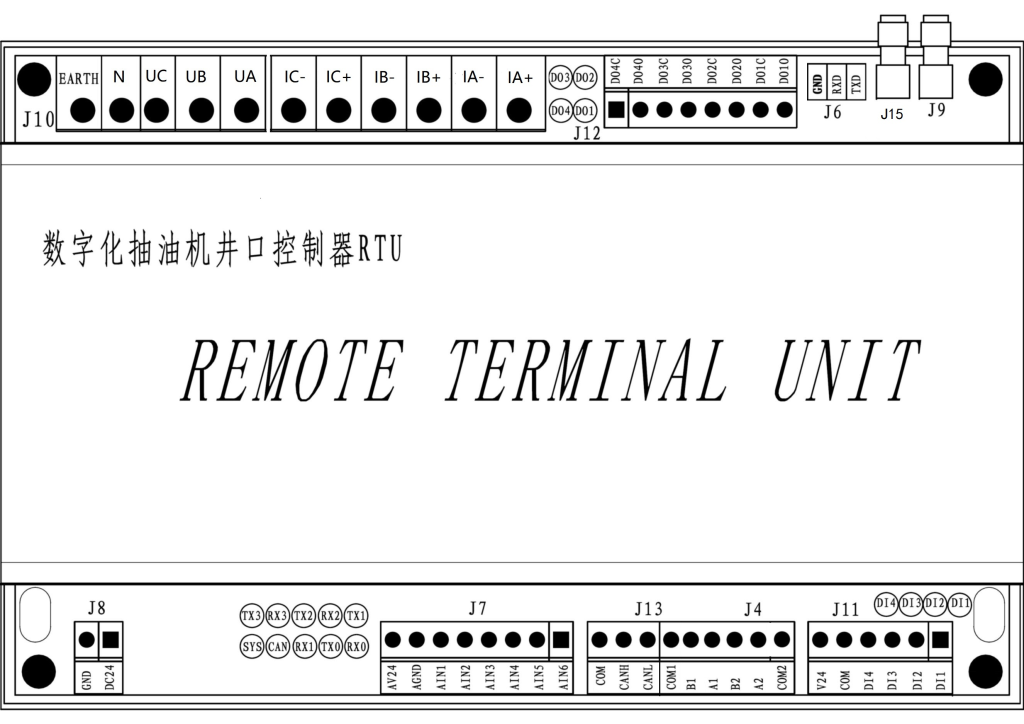

RTU is the core unit of SCADA system to implement the measurement and control of oil Wells, water source Wells and booster pump stations. It is an intelligent remote terminal to realize the real-time collection, storage, alarm and control of the production process data of the above three kinds of measurement and control objects, and meets the application requirements of production sites such as oil Wells, water source Wells and booster pump stations. The design of the standardized digital oilfield RTU is designed according to the application of the field environment and the complex electrical environment, which can meet the various needs of the oilfield and the harsh natural environment and electrical environment. At the same time, the design of the RTU can meet the realization requirements of the intelligent function of the digital oilfield. According to the design concept of standardization and template, the standardized RTU can meet the field application requirements of oil Wells, water source Wells and booster pump stations through simple parameter configuration.

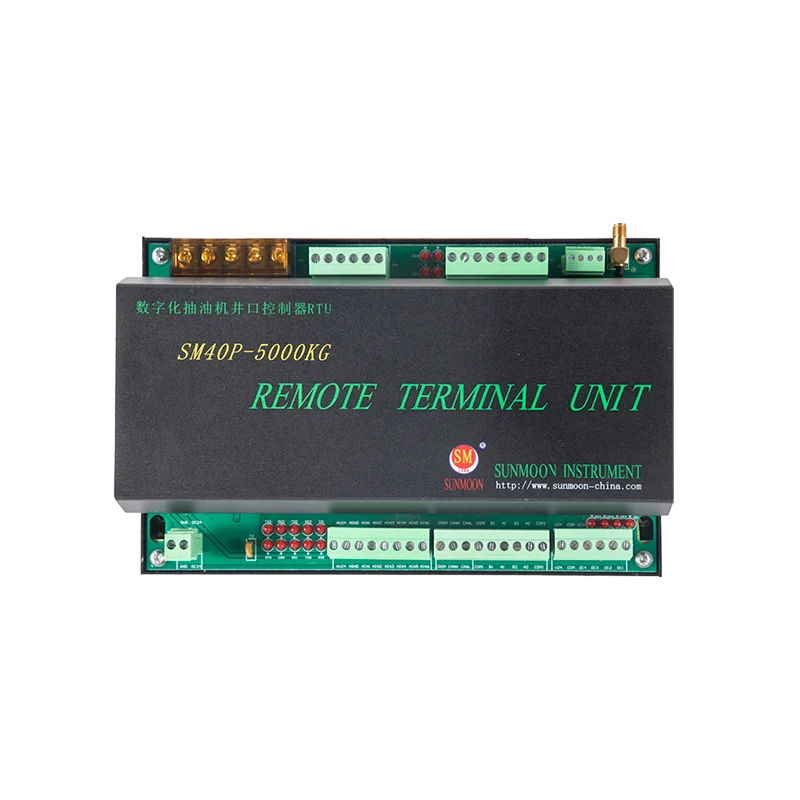

Station RTU Controller Of Measurement And Control Of Oil Well SM40P-5000 KG

Product Description

SM40P-5000 KG Features:

Here is the acquisition simulation device. Multiple acquisition analog devices can be collected through the 816AI extension module cascade, and other use modes can be customized. The introduction is as follows:

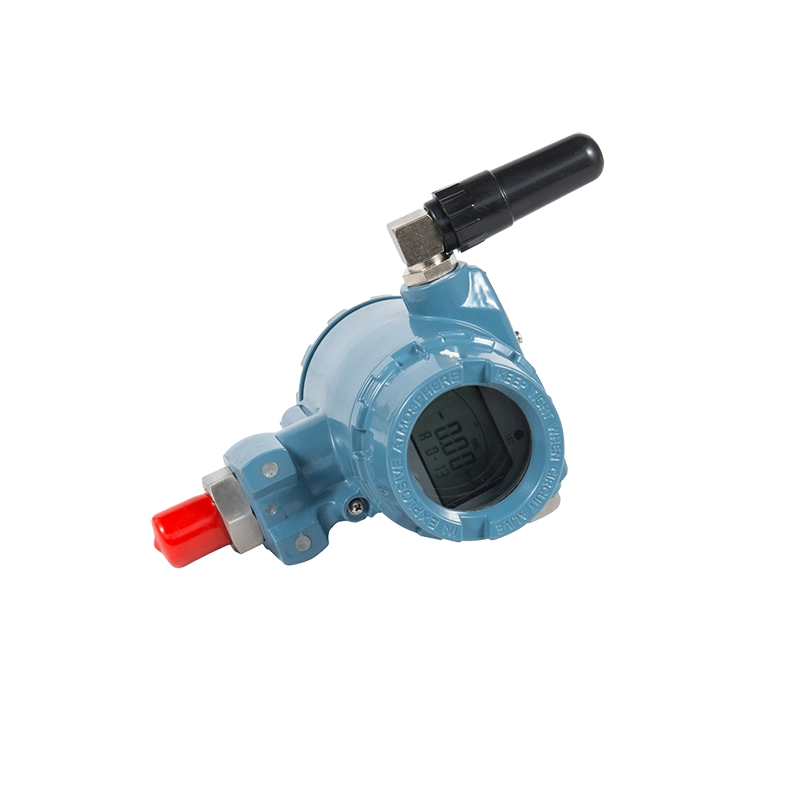

1. Data acquisition mode of RTU: three modes of RTU expansion interface (default mode), wireless ZigBee network and RS485 wired fieldbus network;

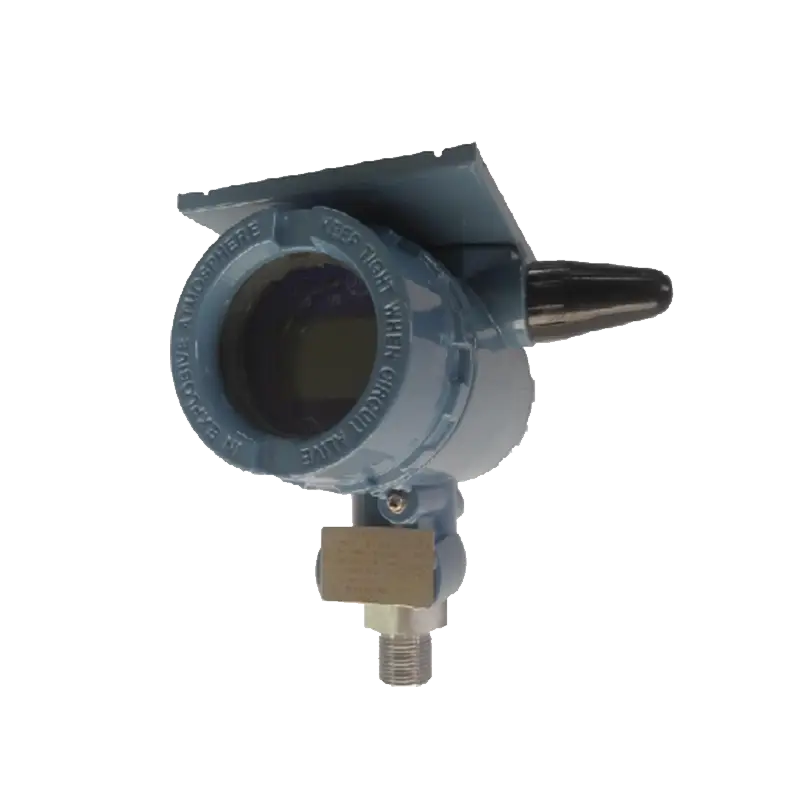

2. Start and stop control mode of RTU: control the start and stop of oil well through the DO interface of RTU;

3. RTU to frequency converter adjustment: through RTU RS485 interface (Modbus RTU protocol);

4. RTU frequency modulation (oil well regulation): it can be realized through DO interface of RTU or RS485 interface of RTU (Modbus RTU protocol);

5. RTU reads the electrical / electric energy data: read the electrical / electrical energy data of the multi-function meter through the RS485 interface (Modbus RTU protocol) of RTU;

6. RTU reads the map data: RTU supports the following map acquisition modes (other modes can be customized);

Wireless load displacement integrated sensor mode;

Wireless load sensor + wireless angular displacement sensor mode;

Wireless load sensor + wireless dead point switch + wireless cable displacement mode;

7. Data sampling mode of RTU: the sampling period of schematic diagram data can be set;

8. The default communication mode between the RTU and the monitoring center is to use the Ethernet interface of the RTU and communicate with the monitoring center through the computer network of optical fiber / wireless network (other customizable)

SM40P-5000 KG Functional description

| Order number | Project | Content |

| 1 | Oil well type | Wireless remote leaflet well monitoring; |

| 2 | Single well graphics acquisition | Work diagram, current diagram, power diagram; |

| 3 | Capture of power map parameters | Maximum and minimum load, stroke and stroke times. |

| 4 | Work map area parameter acquisition | Each work diagram can calculate and show the corresponding work diagram area, which is convenient for the production unit to find the yield changes in time; |

| 5 | Three-phase electrical reference collection | Motor three-phase current, voltage, active power, power factor, etc |

| 6 | Well head parameter collection | Oil pressure (or sink pressure), sleeve pressure (alternative), wellhead temperature (alternative) and other parameters; |

| 7 | Alarm parameter collection | Well opening alarm, well shutdown alarm and power failure alarm (optional) |

| 8 | Frequency conversion parameter collection | Output frequency, output current, output voltage, bus voltage / power. |

| 9 | Well opening and well shutdown control | Remote well opening and remote well shutdown. Controller automatic pumping control |

| 10 | Voice alarm | Before remote well opening and remote well shutdown, the site has a complete voice sound alarm. |

| 11 | Chong times balance adjustment | Upper computer: remote manual input stroke adjustment, balance (automatic status). Controller: SM40P-5000 KG automatically determine and adjust the stroke and balance (automatic status).Frequency converter: frequency converter adjustment stroke time (manual state). |

| 12 | Status lock | Charge, balance not adjusted (locking status), manual / automatic status locking |

| 13 | Local communications | Zigbee Interface, the local wireless digital communication network |

| 14 | Extended communication | RS485 communication between SM40P-5000 KG and third-party devices (alternative) |

| 15 | telecommunication | Full netcom 4G communication, data remote background control room |

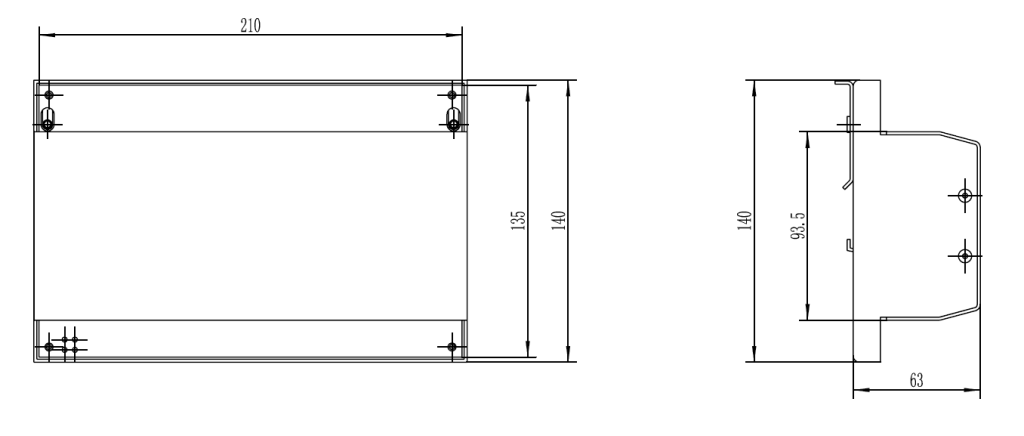

Boundary dimension

Get In Touch With Us !

Related Products

Related Productspartner

partner

download

download