The working principle of tension sensors

Release time: 2025-03-03

A tension-sensor is a device used to measure the tension in materials or objects, and its core working principle is based on strain gauge technology or the piezoelectric effect. When a material is subjected to tension, the strain gauge inside the sensor deforms, causing a change in resistance. This change is converted into an electrical signal through a Wheatstone bridge circuit, which then outputs a voltage or current signal proportional to the tension.

The strain gauge is the key component of a tension-sensor, typically made of metal foil or semiconductor materials. When an external force acts on the sensor, the strain gauge undergoes slight deformation, and its resistance changes accordingly. This change in resistance has a linear relationship with the applied tension, enabling precise measurement of tension.

Piezoelectric tension-sensors operate based on the properties of piezoelectric materials. When piezoelectric materials are subjected to external forces, they generate an internal charge, with the charge amount being proportional to the applied force. By measuring the charge, the magnitude of the tension can be indirectly calculated. Piezoelectric sensors have a fast response time, making them suitable for dynamic tension measurement.

The Wheatstone bridge is the core circuit for signal processing in tension-sensors. It consists of four resistors, one or more of which are strain gauges. When the resistance of the strain gauge changes, the bridge becomes unbalanced, outputting a voltage signal proportional to the tension. This signal, after amplification and filtering, can be used for display or control purposes.

The accuracy of a tension-sensor is influenced by various factors, including the sensitivity of the strain gauge, temperature changes, installation methods, and external electromagnetic interference. To improve measurement accuracy, modern sensors often incorporate temperature compensation techniques and shielding designs to reduce the impact of environmental factors.

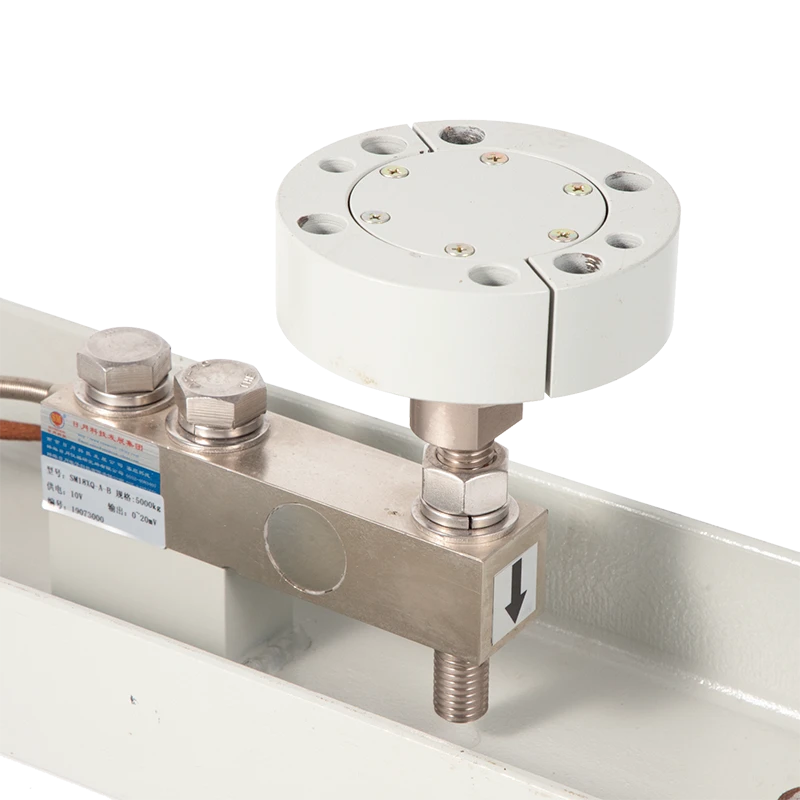

The installation method is crucial to the performance of a tension-sensor. Direct installation involves fixing the sensor directly onto the object under force, suitable for high-precision measurements. Indirect installation, on the other hand, transmits tension through pulleys or bearings, making it suitable for complex working conditions. Regardless of the method, it is essential to ensure that the force transmission path between the sensor and the object is as direct as possible.

Calibration is a critical step in ensuring the measurement accuracy of a tension-sensor. By applying known force values and recording the output signals, a force-signal relationship curve for the sensor can be established. Regular calibration can correct performance drift caused by long-term use or environmental changes, ensuring the reliability of measurement results.

Tension-sensors offer a variety of output signal types, including analog and digital signals. Analog signals, such as 4-20mA or 0-10V, are suitable for short-distance transmission; digital signals, such as RS485 or CAN bus, are ideal for long-distance and high anti-interference requirements. Choosing the appropriate signal type helps improve the overall performance of the system.

In practical applications, tension-sensors are commonly used to monitor and control tension during production processes. For example, in printing machines, sensors ensure constant paper tension to prevent paper breaks or wrinkles; in cable manufacturing, sensors control wire drawing tension to ensure product quality.

When maintaining tension-sensors, it is necessary to regularly clean the surface to avoid the accumulation of dust and oil; check for loose or damaged connection lines; and avoid overloading. In harsh environments, protective devices can be installed to extend the sensor’s lifespan.

SUNMOON’s product portfolio includes state-of-the-art digital sensors, portable wireless telemetry diagnostic instruments, downhole liquid level monitoring systems, digital wireless networks for remote monitoring and control in oil fields, and IoT (Internet of Things) systems for measurement and control in oil and gas production. If you have a need to purchase precision tension-sensors, please feel free to contact us at any time.

/>

/> />

/>