ما هي أجهزة استشعار خلايا تحميل حقول النفط؟

وقت الإصدار: 2025-08-16

جدول المحتويات

في عمليات استخراج النفط وعملياته، يُعدّ رصد المعدات بدقة وجمع البيانات أمرًا بالغ الأهمية. وخاصةً في البيئات عالية الطلب، مثل الحفر والتكسير والضخ، فإن أي عطل في المعدات أو خطأ تشغيلي قد يُؤدي إلى خسائر اقتصادية كبيرة أو مخاطر أمنية. لضمان عمليات مستقرة وآمنة، أجهزة استشعار خلايا تحميل حقول النفط أصبحت هذه التقنيات أساسية. تقدم هذه المقالة لمحةً تفصيليةً عن مبادئ عملها، وتطبيقاتها الرئيسية، وأهميتها في عمليات حقول النفط.

مبدأ عمل أجهزة استشعار خلايا تحميل حقول النفط

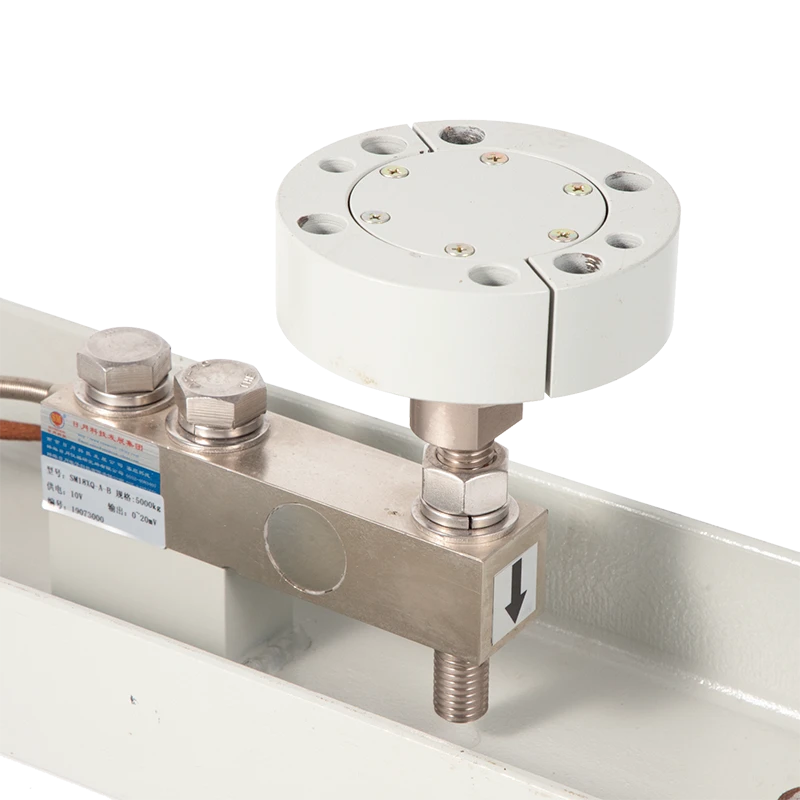

مستشعرات خلايا حمل حقول النفط هي أجهزة تُستخدم لقياس القوة أو الوزن أو الضغط، وتُستخدم على نطاق واسع في أنظمة مراقبة حقول النفط. يعتمد تشغيلها على: تكنولوجيا مقياس الانفعال، الذي يحسب الحمل عن طريق الكشف عن التشوه الهيكلي. تتم العملية كما يلي:

- تحميل التطبيق:عندما يتم تطبيق حمل خارجي - مثل الزيت أو الغاز أو رؤوس الحفر أو وزن المعدات - على المستشعر، يتعرض هيكله لتشوه طفيف.

- كشف السلالةتستجيب مقاييس الانفعال المدمجة في المستشعر للتشوه بتغيير مقاومتها الكهربائية. تتميز هذه المقاييس بحساسيتها العالية، حيث يمكنها اكتشاف حتى أصغر التشوهات.

- تحويل الإشارة:يتم تحويل تغييرات المقاومة إلى إشارات كهربائية وإرسالها إلى نظام مراقبة، والذي يعرض بعد ذلك قيم الحمل أو الضغط.

تضمن هذه التقنية مراقبة حمولة المعدات والضغط في الوقت الفعلي، مما يتيح للمشغلين إجراء التعديلات في الوقت المناسب ومنع فشل المعدات أو المخاطر المحتملة على السلامة.

تطبيقات أجهزة استشعار خلايا تحميل حقول النفط

تُستخدم مستشعرات خلايا أحمال حقول النفط على نطاق واسع في مختلف مراحل عمليات حقول النفط، خاصةً حيثما يتطلب الأمر مراقبة عالية الدقة للأحمال وجمع البيانات. تشمل التطبيقات الرئيسية ما يلي:

مراقبة معدات حقول النفط

غالبًا ما تتحمل معدات مثل منصات الحفر وأجهزة الاستخراج وآلات رؤوس الآبار أحمالًا كبيرة. تراقب مستشعرات خلايا الحمل هذه الأحمال آنيًا، مما يضمن التشغيل ضمن الحدود الآمنة ويمنع الأضرار أو الحوادث الناجمة عن الحمل الزائد. على سبيل المثال، أثناء الحفر، يمكن للمستشعرات تتبع حمل لقمة الحفر لضمان عمليات آمنة وفعالة.

عمليات التكسير الهيدروليكي

التكسير الهيدروليكي تقنية شائعة في استخراج النفط، حيث تلعب مستشعرات خلايا الحمل دورًا حاسمًا. فهي تراقب تغيرات وزن سائل التكسير، مما يساعد المشغلين على التحكم الدقيق في ضغط وحجم السائل، مما يضمن تكسيرًا آمنًا وفعالًا.

أنظمة الضخ والنقل

تتولى أنظمة الضخ والنقل إدارة تدفق السوائل، مثل النفط الخام والغاز الطبيعي. تراقب مستشعرات خلايا الحمل حمولة السوائل في الأنابيب، مما يمنع الحمل الزائد الذي قد يؤدي إلى تمزق الأنابيب أو تسربها.

تخزين ونقل النفط والغاز

في التخزين والنقل، تقيس المستشعرات وزن السوائل في الخزانات والمركبات. تضمن مراقبة وزن السوائل في الخزانات تخزينًا آمنًا، بينما تمنع مراقبة حمولة المركبات التحميل الزائد وتضمن الالتزام بالمواصفات أثناء النقل.

مراقبة حمولة المعدات

تعمل المعدات الميكانيكية، مثل منصات الحفر والمضخات، في ظروف تشغيل عالية الكثافة. تتتبع مستشعرات خلايا الحمل أحمالها آنيًا، مما يُمكّن من الكشف المبكر عن أي ظروف غير طبيعية، مما يمنع حدوث أي تلف أو توقف.

إدارة آبار النفط والغاز

تتطلب إدارة آبار النفط والغاز مراقبة أحمال المعدات للحفاظ على الأداء الأمثل. تضمن المستشعرات تشغيل المعدات تحت الأحمال المثالية، مما يُحسّن كفاءة الإنتاج واستقراره.

مزايا وأهمية أجهزة استشعار خلايا تحميل حقول النفط

ال تطبيق أجهزة استشعار خلايا الحمل في حقول النفط تُحسّن عمليات التشغيل دقة إدارة المعدات، وتُزوّد المُشغّلين برؤى مُستندة إلى البيانات. من أهمّ مزاياها:

- مراقبة عالية الدقة:يوفر قياسات دقيقة للحمل والضغط لضمان عمليات مستقرة.

- التحكم في الوقت الحقيقي:يتيح للمشغلين مراقبة حالة المعدات بشكل مستمر ومعالجة المخاطر على الفور.

- ضمان السلامة:يمنع التحميل الزائد وفشل المعدات، مما يقلل من مخاطر الحوادث.

- انخفاض تكاليف التشغيل:تمنع المراقبة الدقيقة هدر الموارد وتكاليف الصيانة الإضافية، مما يحسن الكفاءة.

- عمر افتراضي أطول للمعدات:تتيح مراقبة الحمل المستمر إمكانية الصيانة والاستبدال في الوقت المناسب، مما يؤدي إلى إطالة عمر المعدات.

خاتمة

تُعدّ مستشعرات خلايا الحمل في حقول النفط مكونات أساسية في عمليات حقول النفط، حيث تلعب دورًا محوريًا في ضمان سلامة المعدات، وتحسين كفاءة الإنتاج، وتقليل المخاطر التشغيلية. ومع تطور الأتمتة والرقمنة في قطاع حقول النفط، تكنولوجيا مستشعر خلية الحمل وسوف تستمر في التطور، لتصبح جزءًا لا يتجزأ من عمليات حقول النفط المستقبلية.

/>

/> />

/>