Comment les transmetteurs de pression sans fil assurent le fonctionnement des équipements

Date de sortie : 21/05/2025

Dans les systèmes d'automatisation et de surveillance industriels, les transmetteurs de pression sans fil permettent non seulement de surveiller avec précision les variations de pression, mais aussi de transmettre des données en temps réel, contribuant ainsi à l'efficacité opérationnelle et à la gestion des équipements des entreprises. Grâce à ces transmetteurs, la stabilité et la sécurité des équipements sont grandement garanties, améliorant ainsi l'efficacité globale de la production.

Principe de fonctionnement du transmetteur de pression sans fil

Transmetteurs de pression sans fil de haute précision Les données de pression des équipements sont collectées grâce à des capteurs et transmises au système de surveillance central via la technologie sans fil. Contrairement aux transmetteurs de pression filaires traditionnels, la transmission sans fil ne nécessite pas la pose de câbles et de lignes complexes, ce qui simplifie non seulement l'installation, mais réduit également le risque de défaillance des équipements.

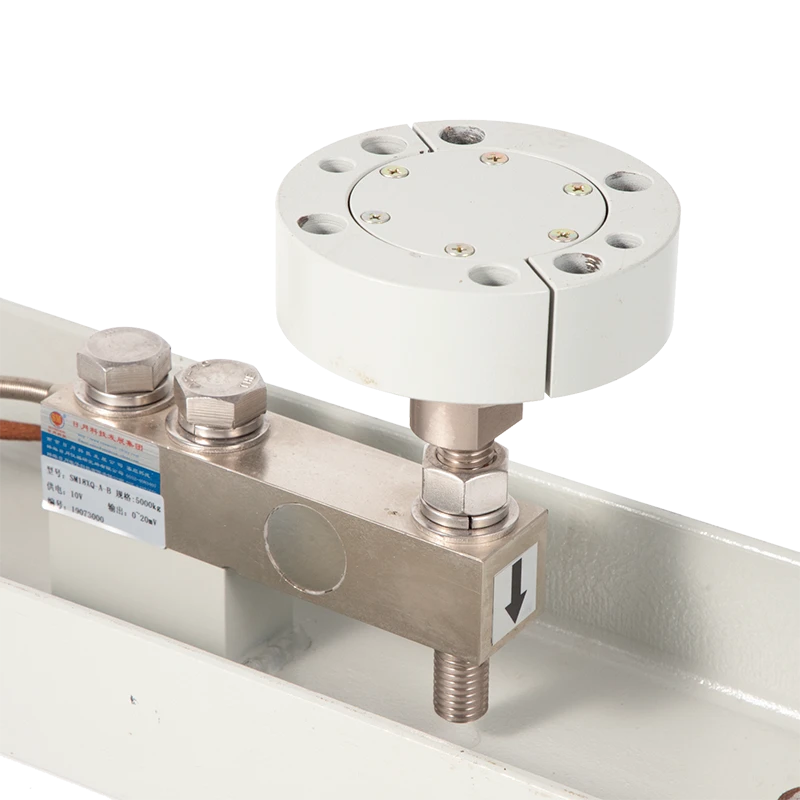

Les transmetteurs de pression sans fil sont généralement composés de capteurs de pression, de modules de traitement du signal, de modules de communication sans fil et de batteries. Les capteurs de pression sont très sensibles aux variations de pression et peuvent convertir les valeurs de pression en signaux électriques. Après amplification, filtrage et conversion du signal émis par le capteur, le module de traitement du signal transmet les données au centre de surveillance ou au système de contrôle via le module de communication sans fil. La batterie assure l'alimentation de l'ensemble du système, garantissant ainsi un fonctionnement stable et durable de l'équipement dans différents environnements.

Avantages des transmetteurs de pression sans fil pour garantir le fonctionnement des équipements

Surveillance et transmission de données en temps réel

Les transmetteurs de pression sans fil permettent de surveiller l'état de fonctionnement des équipements en temps réel et de transmettre les données de pression au système de surveillance à distance via les réseaux sans fil. Ainsi, où que se trouve l'équipement, le personnel peut le surveiller en temps réel via les réseaux sans fil. Lorsque la pression de l'équipement dépasse la plage définie, le système déclenche une alarme à temps pour éviter toute panne ou tout accident dû à une pression anormale.

Maintenance préventive

Les transmetteurs de pression sans fil peuvent non seulement fournir les valeurs de pression actuelles, mais aussi prédire l'état de fonctionnement des équipements grâce à l'analyse des données. Lorsque la pression de l'équipement présente une tendance anormale, le système peut anticiper les pannes potentielles et effectuer la maintenance à l'avance pour éviter les temps d'arrêt ou les pannes graves. La maintenance préventive réduit les coûts de maintenance et améliore la disponibilité des équipements et l'efficacité du travail.

Installation et maintenance simplifiées

Par rapport aux capteurs filaires traditionnels, transmetteurs de pression sans fil faciles à entretenir Ils ne nécessitent pas de câblage complexe et n'affectent pas la stabilité de la transmission en cas de problèmes de ligne. En particulier dans les endroits où le câblage est impossible ou où des déplacements fréquents sont nécessaires, les transmetteurs de pression sans fil peuvent réduire considérablement la difficulté d'installation et de maintenance.

Haute fiabilité et capacité anti-interférence

Les transmetteurs de pression sans fil modernes utilisent une technologie de communication avancée et disposent d'une forte capacité anti-interférence. Dans les environnements industriels complexes, ils garantissent une transmission de données stable et réduisent les pertes de données ou les erreurs de transmission causées par les interférences électromagnétiques ou l'atténuation du signal.

Économie d'énergie et protection de l'environnement

La plupart des transmetteurs de pression sans fil adoptent une conception basse consommation et sont équipés de batteries longue durée. Cela prolonge considérablement la durée de vie de l'équipement et évite le remplacement fréquent des batteries, réduisant ainsi les coûts de maintenance et étant respectueux de l'environnement.

Conclusion

Dans le processus de production industrielle, le fonctionnement normal des équipements est directement lié à l'efficacité de la production et à la sécurité de l'entreprise. Grâce à leur efficacité, leur intelligence et leur fiabilité, transmetteurs de pression sans fil peut surveiller les changements de pression de l'équipement en temps réel, détecter les risques de défaillance potentiels à l'avance, éviter l'apparition de nombreux accidents de défaillance de l'équipement, assurer le fonctionnement stable de l'équipement et aider les entreprises à améliorer l'efficacité de la production et le niveau de gestion des opérations.

/>

/> />

/>