O que é uma célula de carga de extensômetro

Horário de lançamento: 30/07/2025

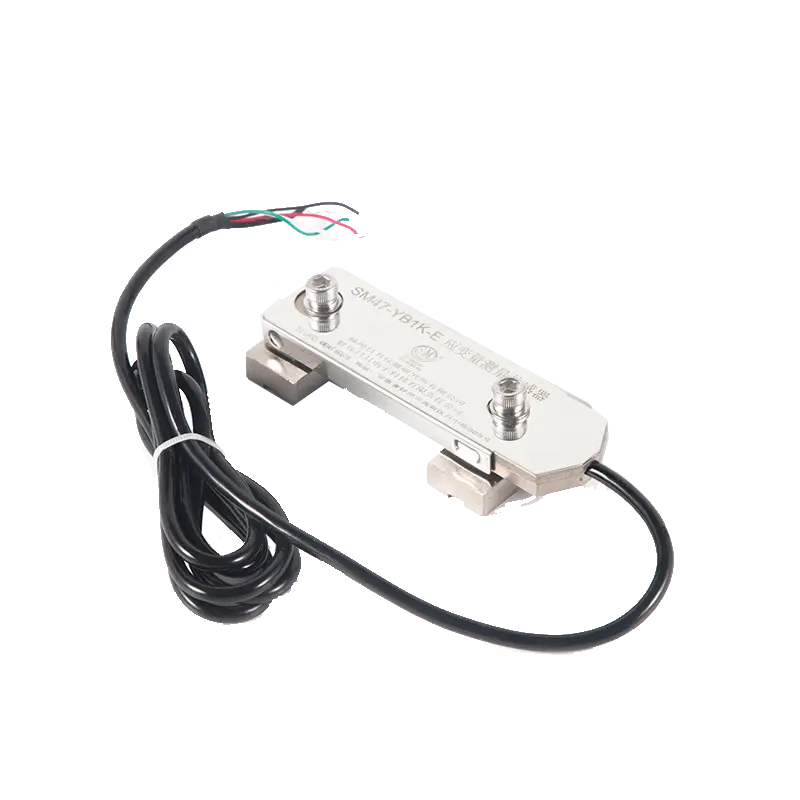

Nos setores industrial e tecnológico, a medição precisa de força e peso é crucial. A célula de carga Strain Gauge, um sensor essencial que converte grandezas mecânicas como força ou peso em sinais elétricos, tornou-se uma das ferramentas de medição mais comuns e importantes em aplicações industriais. Com sua alta precisão e ampla gama de aplicações, este sensor desempenha um papel fundamental no fornecimento de dados de medição confiáveis em diversos setores. Seu princípio de operação e estrutura são altamente sofisticados, utilizando o efeito de deformação para converter pequenas deformações mecânicas em sinais elétricos detectáveis.

Células de carga de extensômetro Princípio de funcionamento

O Princípio básico da célula de carga do extensômetro é baseado no efeito de tensão, que afirma que a resistência elétrica de um material condutor muda quando ele sofre deformação. Em termos simples, quando o sensor é submetido a uma força externa, o elemento elástico dentro do sensor sofre pequenas deformações. Essa deformação faz com que os extensômetros fixados a ele também se deformem, levando a alterações na resistência. Medindo essas pequenas alterações na resistência, a força aplicada pode ser calculada.

Células de carga de extensômetro Processo de trabalho

- Aplicando Força Externa:Quando o objeto a ser medido aplica uma força, o elemento elástico dentro da célula de carga se deforma ligeiramente.

- Deformação do extensômetro:Como os extensômetros estão firmemente fixados ao elemento elástico, eles se deformam à medida que o elemento elástico se deforma (seja esticando ou comprimindo).

- Mudança de Resistência: A deformação dos extensômetros leva a alterações em seu comprimento e área da seção transversal, o que, por sua vez, causa alterações na resistência. A resistência aumenta quando esticada e diminui quando comprimida.

- Ponte de WheatstonePara medir essas pequenas variações na resistência, vários extensômetros (geralmente quatro) são conectados em um circuito de ponte de Wheatstone. Essa ponte amplifica a variação na resistência, facilitando sua detecção.

- Tensão de saída: Quando nenhuma força externa é aplicada, a ponte está em equilíbrio e a tensão de saída é zero. Quando uma força externa deforma o elemento elástico, ela causa uma alteração na resistência do extensômetro, desequilibrando a ponte e gerando um sinal de tensão fraco, proporcional à força aplicada.

- Processamento de Sinal:Esse sinal de voltagem fraca é então amplificado e digitalizado por meio de amplificadores e um conversor analógico-digital (conversor A/D), convertendo-se, por fim, em uma leitura de força ou peso que pode ser exibida ou usada por um sistema de controle.

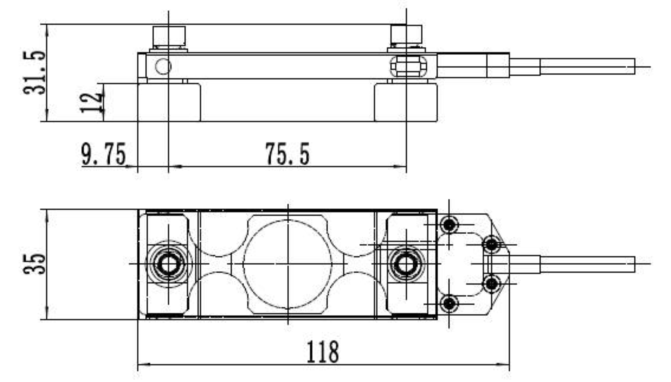

Células de carga de extensômetro Estrutura

O Célula de carga de extensômetro consiste principalmente em dois componentes principais:

- Elemento Elástico (Elemento de Flexão): Este é o corpo metálico do sensor, normalmente feito de aço-liga de alta resistência ou alumínio. O design do elemento elástico é altamente preciso, permitindo que ele sofra pequenas deformações elásticas previsíveis quando uma força externa é aplicada, sendo capaz de retornar à sua forma original quando a força é removida.

- Medidores de tensão: Estes são os elementos sensores que convertem a deformação mecânica do elemento elástico em um sinal elétrico. Os extensômetros são normalmente feitos de fios metálicos finos ou folhas metálicas dispostas em um padrão de grade e firmemente fixadas ao elemento elástico.

Células de carga de extensômetro Aplicações

Devido à sua alta precisão, estabilidade e ampla faixa de medição, as células de carga extensômetro têm sido amplamente utilizadas em diversos setores. Algumas das áreas de aplicação comuns incluem:

- Sistemas de Pesagem Industrial:Como balanças de caminhão, balanças de veículos, balanças suspensas, balanças de embalagem e balanças de lote, que são usadas para medição e controle precisos de pesos de materiais em indústrias de logística e armazenagem.

- Máquinas de teste de materiais: Usado para medição precisa de propriedades mecânicas de materiais em testes de tração, compressão, flexão e fadiga, fornecendo dados precisos para pesquisa e testes de materiais.

- Controle de Processo: Aplicado no monitoramento de níveis ou pesos de tanques, silos e reatores para permitir o controle automatizado em vários processos de fabricação.

- Aeroespacial: Usado para testes de estresse, deformação e fadiga de asas de aeronaves, motores e componentes estruturais, garantindo a segurança e a durabilidade das estruturas de aviação.

- Equipamentos Médicos: Usado em balanças médicas e dispositivos de reabilitação, fornecendo dados fisiológicos precisos para auxiliar os médicos no diagnóstico e tratamento.

- Engenharia Civil: Aplicado no monitoramento de estresse e avaliação de saúde de grandes estruturas, como pontes, barragens e edifícios, garantindo a segurança e a estabilidade de projetos de construção.

- Indústria automotiva: Usado em testes de colisão, testes de sistema de suspensão e medição de torque do motor para melhorar a segurança e o desempenho do veículo.

Diferenças entre os diferentes tipos de células de carga

| Características | Células de carga de extensômetro | Células de Carga Hidráulicas | Células de Carga Pneumáticas | Células de carga piezoelétricas |

| Princípio de operação | Converte deformação em voltagem | Converte força em pressão hidráulica | Converte força em pressão de ar | Converte força em carga elétrica |

| Precisão | Alto desempenho, comum na indústria | Lento, usado em ambientes hostis | Alta pressão, resposta lenta | Extremamente sensível, para medições dinâmicas |

| Velocidade de resposta | Rápido, adequado para estático e dinâmico | Lento | Lento | Extremamente rápido, alcance de microssegundos |

| Principais vantagens | Alta precisão, estabilidade, baixo custo | Não afetado pela temperatura, intrinsecamente seguro | Não afetado pela temperatura, intrinsecamente seguro | Alta velocidade de resposta, ampla faixa de medição |

| Principais desvantagens | Suscetível a flutuações de temperatura | Sujeito a vazamentos de fluidos, alta manutenção | Vulnerável à instabilidade da fonte de ar | Adequado apenas para forças dinâmicas |

| Aplicações típicas | Balanças, máquinas de teste, controle de processos | Pesagem de tanques, pesagem industrial | Ambientes à prova de explosão | Teste de choque, vibração, pressão de combustão |

Conclusão

Células de carga de extensômetroCom sua alta precisão, estabilidade e versatilidade de aplicações, tornaram-se componentes indispensáveis em diversos setores. Sejam utilizados na produção industrial para pesagens precisas ou em pesquisas, na área médica e aeroespacial para medições precisas, eles provaram ser confiáveis e cruciais no fornecimento de dados críticos. Com os contínuos avanços tecnológicos, as aplicações de células de carga strain gauge continuarão a se expandir, oferecendo soluções de medição mais precisas e confiáveis para indústrias em todo o mundo.

/>

/> />

/>