Как беспроводные датчики перемещения ускоряют получение информации

Время выпуска: 13 сентября 2025 г.

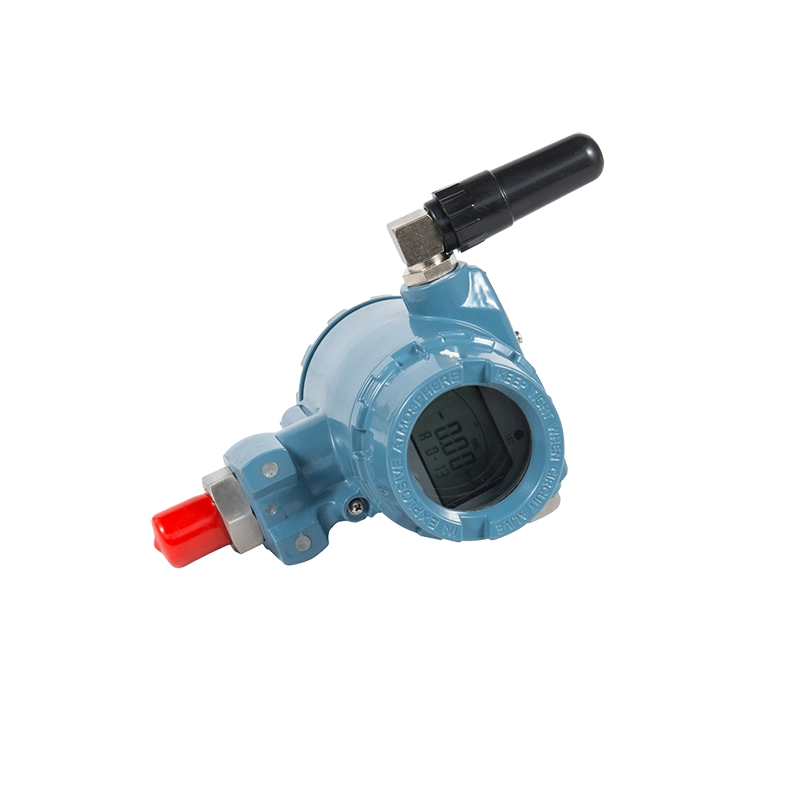

Традиционные датчики перемещения требуют сложной проводки, что не только увеличивает стоимость и сложность установки, но и ограничивает область применения. Представьте себе, что вам нужно отслеживать мельчайшие деформации моста через широкую реку или точное перемещение роботов в опасном производственном цехе — проводные соединения явно непрактичны. Появление беспроводные датчики смещения решает эти проблемы. Освободившись от ограничений, связанных с кабелями, они передают данные по беспроводной связи, делая получение информации более свободным и гибким, чем когда-либо прежде.

Различные типы беспроводных датчиков перемещения

Беспроводные датчики перемещения не относятся к одному типу устройств, а делятся на различные типы в зависимости от принципа работы и сфер применения. Понимание их характеристик помогает нам лучше выбрать подходящий инструмент для конкретной задачи.

- Беспроводные ультразвуковые датчики смещения Эти датчики измеряют расстояние, излучая и принимая ультразвуковые волны, подобно тому, как летучие мыши используют эхолокацию. Эти датчики относительно недорогие, имеют большой диапазон измерения и широко используются для контроля уровня жидкостей и материалов, а также для определения расстояния до крупных объектов.

- Беспроводные лазерные датчики смещения Используя лазерные лучи для точных измерений, эти датчики характеризуются высокой точностью и быстрым откликом. Они особенно подходят для приложений, требующих точности до миллиметра, таких как сканирование профиля объекта и определение размеров деталей на автоматизированных производственных линиях.

- Беспроводные датчики смещения троса Эти датчики определяют смещение, измеряя удлинение троса. Они обеспечивают широкий диапазон измерений и просты в установке. Эти датчики широко используются в приложениях, требующих измерения больших смещений, например, для контроля стрел кранов, деформационных швов мостов и осадки плотин.

- Беспроводные индуктивные датчики перемещения (включая LVDT) Эти датчики, основанные на принципе электромагнитной индукции, определяют перемещение, измеряя изменения индуктивности катушки. Они просты по конструкции, обладают хорошей водо- и пылезащитой и подходят для использования в суровых промышленных условиях. Высокоточные LVDT-датчики широко используются в прецизионной обработке и аэрокосмической промышленности.

Сравнение различных типов беспроводных датчиков перемещения

| Тип | Преимущества | Недостатки | Типичные области применения |

|---|---|---|---|

| Ультразвуковой | Большой диапазон измерений, низкая стоимость | Зависит от температуры и влажности окружающей среды, относительно низкая точность | Контроль уровня жидкости/материала, обход препятствий с крупными объектами |

| Лазер | Высокая точность, быстрый отклик | Высокая стоимость, подверженность воздействию света и пыли | Автоматизированные производственные линии, позиционирование роботов, прецизионные измерения |

| Веревка | Чрезвычайно большой диапазон измерений, гибкая установка | Стальной трос изнашивается, могут возникнуть механические зазоры | Мониторинг осадки мостов/плотин, стрел кранов |

| Индуктивный | Сильная защита от помех, водонепроницаемость и пылезащита | Относительно небольшой диапазон измерений, требует вспомогательной электроники | Суровые промышленные условия, точная обработка |

Общие среды использования

Благодаря своему удобству, беспроводные датчики смещения широко используются в различных сценариях, включая:

- Промышленная автоматизация: Используется в роботах, автоматизированных производственных линиях и автоматически управляемых транспортных средствах для позиционирования, обхода препятствий и точного управления.

- Мониторинг состояния конструкций: используется для мониторинга смещения, осадки и деформации мостов, туннелей, плотин и высотных зданий, обеспечивая раннее предупреждение о потенциальных рисках.

- Логистика и складирование: Используется в системах автоматизации склада для измерения высоты укладки товаров и точного позиционирования вилочных погрузчиков.

- Сельскохозяйственное поле: Используется для контроля движения сельскохозяйственной техники, а также открытия и закрытия вентиляционных систем в теплицах.

- Медицинское оборудование: Используется в реабилитационных устройствах и хирургических роботах для точного измерения и контроля.

Важные соображения при использовании

Для обеспечения точности и надежности беспроводных датчиков перемещения следует учитывать следующие моменты:

- Помехи беспроводного сигнала: Беспроводная связь чувствительна к помехам от других электронных устройств или электромагнитных полей. При установке избегайте мест с мощными беспроводными устройствами или сильными электромагнитными полями.

- Управление питанием: Беспроводные датчики обычно работают от батареи, поэтому важно регулярно проверять уровень заряда батареи и выбирать подходящий тип батареи в зависимости от частоты использования и температуры окружающей среды.

- Экологическая адаптация: Выбирайте датчики с соответствующими степенями защиты (например, IP67) и диапазонами рабочих температур в зависимости от конкретной среды применения, чтобы предотвратить влияние пыли, влаги или экстремальных температур на производительность.

- Место установки: Убедитесь, что датчик надёжно установлен, а направление его измерения совпадает с направлением движения измеряемого объекта. Любое ослабление крепления или несоосность могут привести к ошибкам измерения.

- Протоколы связи: Выберите подходящий протокол беспроводной связи (например, Wi-Fi, Bluetooth, ZigBee или LoRa) в зависимости от потребностей приложения. Каждый протокол имеет свои преимущества и недостатки. Например, Wi-Fi обеспечивает высокую скорость, но высокое энергопотребление, а LoRa — низкое энергопотребление, но более низкую скорость передачи данных.

Заключение

С широким распространением технологий Интернета вещей и 5G будущее беспроводные датчики смещения Выглядит всё более многообещающе. Эти датчики не только помогут повысить эффективность промышленного производства и обеспечить безопасность инфраструктуры, но и внесут вклад в создание более интеллектуального и взаимосвязанного будущего.

/>

/> />

/>