- Advanced compensation process, with a variety of temperature range to choose from.

- Long-term online measurement, excellent stability.

- A variety of output forms for users to choose, can measure positive and negative torque.

- 4. Can be designed according to user requirements non-standard.

SM504-LY Torque sensor

Product Description

Used to measure torsional moment, stirring moment, steering torque, etc., widely used in automatic control and scientific experiments of non-continuous rotation torque measurement. Can be designed according to user requirements non-standard.

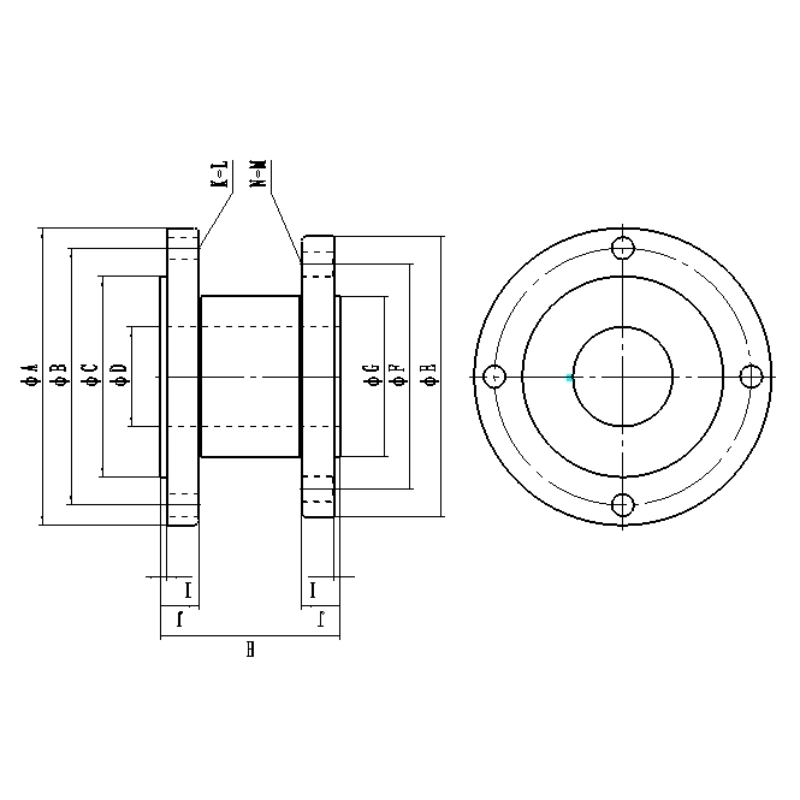

Dimensions(In mm. 1mm=0.03937 inches)

| LI 量程(N.m) | A | B | C | D | E | F | G | H | I | J | K | L | M | N |

| 300 | 185 | 160 | 125 | 62 | 175 | 140 | 100 | 112 | 4 | 24 | 4 | Φ14 | M16 | 4 |

| 600 | 225 | 195 | 150 | 78 | 210 | 165 | 130 | 130 | 4 | 24 | 4 | Φ18 | M20 | 4 |

| 1200 | 275 | 235 | 180 | 88 | 300 | 254 | 200 | 158 | 4 | 25 | 4 | Φ22 | M16 | 8 |

| 20000 | 415 | 356 | 198 | 165 | 415 | 356 | 260 | 235 | 5 | 30 | 8 | Φ33 | M30 | 8 |

SM504-LY Torque sensor Specification:

| Type | Technical parameters |

| Nominal load range | 0.5~300kg |

| Power supply | 10~12 VDC |

| Zero balance | 1.0±% of rated output |

| Analog output | 2.0±0.015mV/V |

| Input resistance(Rlc) | 380±5Ω(ohms) |

| Output resistance(Ro) | 350±2Ω(ohms) |

| Insulation resistance | ≥5000 MΩ(Mege-Ohms) |

| Class precision | 0.05%FS |

| Effect of temperature | 0.05%FS/10℃ |

| Operating temperature | -40~+85℃ |

| Safe Load Limit | 200% FS |

| Safety margin against yielding | 300% FS |

| Safety margin against breakage | 500% FS |

| Material material | High performance alloy steel or (chromium ratio>15% stainless steel) |

| Protection type | IP66 |

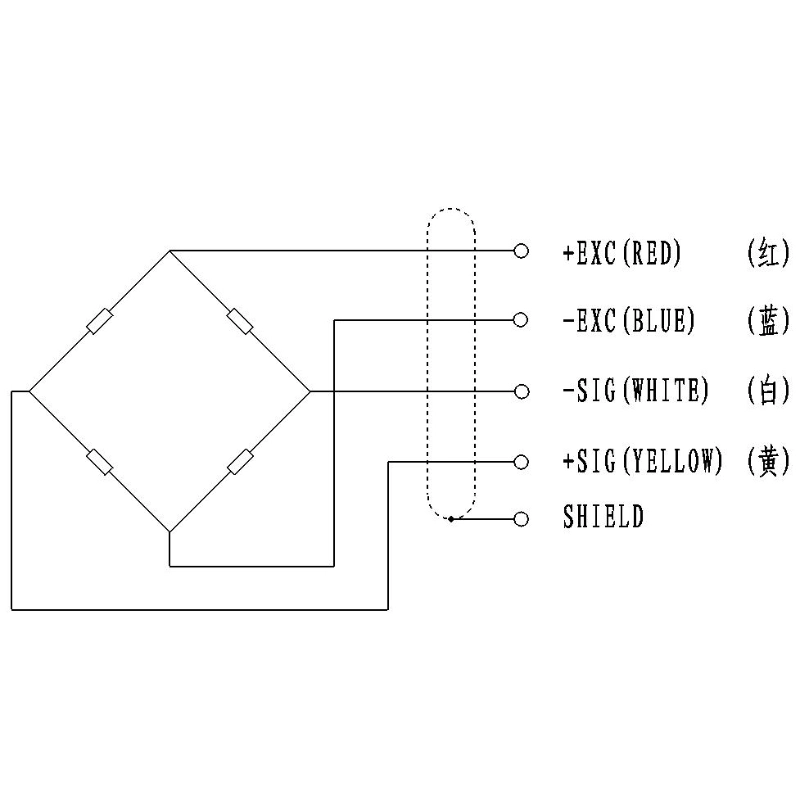

Circuit Diagram 电路图:

Red: +input

Blue: -input

White: +output

Yellow: -output

Torque sensors are devices used to measure the twisting torque applied to an object. They play an important role in various industrial and engineering applications, helping to enhance efficiency and safety.

Working Principle

Torque sensors typically operate based on strain gauge, optical, or electromagnetic principles. They calculate torque values by detecting changes in deformation or other variations in the object when torque is applied.

Types

Strain Gauge Type: Utilizes strain gauges to measure the strain changes in materials during torsion.

Optical Type: Measures torque using optical methods, offering high precision and resistance to interference.

Brushless Motor Type: Used for non-contact measurements in rotating devices.

Applications

Automotive Industry: Measures torque in engines, transmission systems, and axles to optimize performance and safety.

Manufacturing: Monitors torque during production processes to ensure assembly quality and consistency.

Aerospace: Used in torque testing of aircraft components to ensure safety and reliability.

Energy Sector: Measures torque in wind turbines and other energy devices to ensure effective operation.

Advantages

High Precision: Provides accurate torque measurements, ensuring quality in engineering and products.

Real-Time Monitoring: Suitable for real-time data acquisition and feedback in dynamic systems.

Strong Reliability: Designed to withstand various working environments, ensuring long-term stable operation.

Installation and Maintenance

Torque sensors are usually designed for easy installation and integration into existing systems. Regular maintenance and calibration are key to ensuring their accuracy.

Get In Touch With Us !

Related Products

Related Productspartner

partner

download

download