- High Precision: Provides accurate tension measurement, enhancing operational safety.

- Durability: Sturdy design adapts to various harsh working environments and has a long service life.

- Easy Installation and Maintenance: Simple structure allows for easy integration with existing systems and maintenance.

- Side Pressure Design: Accurately senses the force transmitted by the wire rope through a side pressure structure, avoiding direct tension loads.

- Real-Time Monitoring: Monitors wire rope tension to ensure it remains within safe limits and prevents overload.

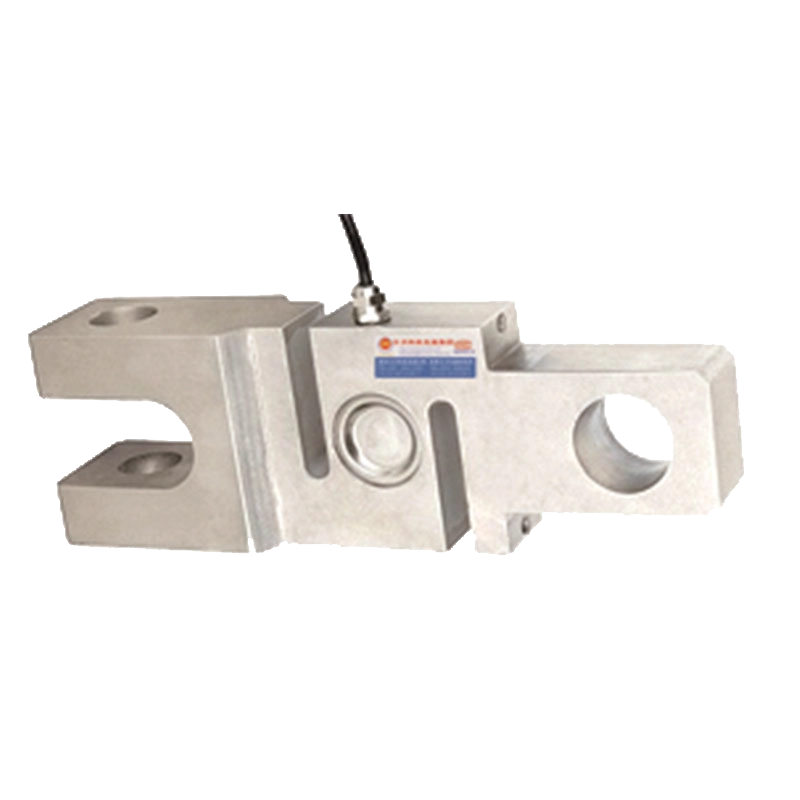

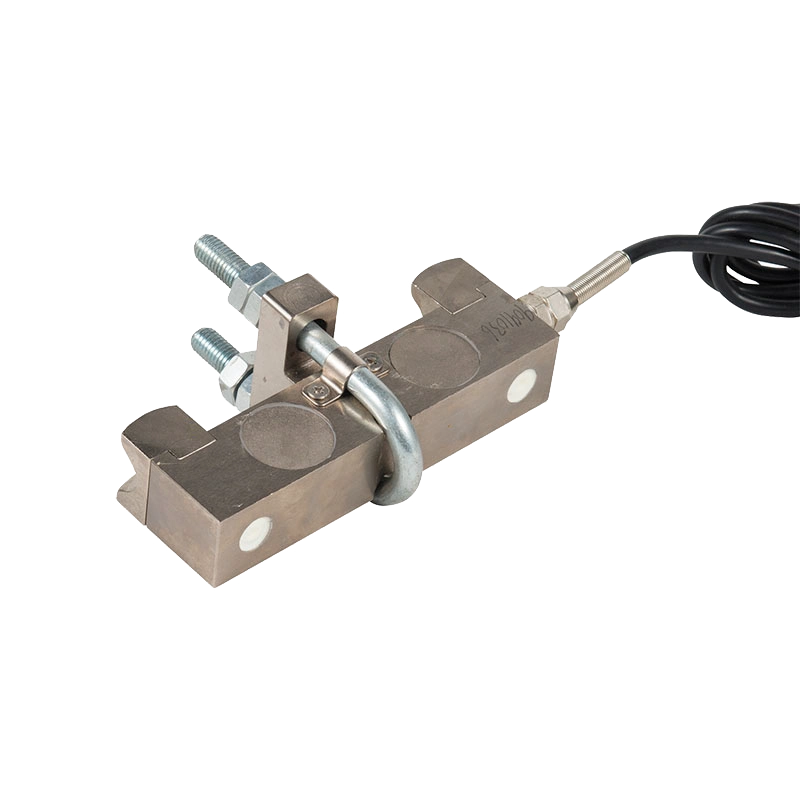

Type SM40F Side Pressure Load Cell

Product Description

The sensor is made of alloy steel or stainless steel and has a unique press-type structure. The working principle is that the wire rope is fixed on the sensor through the U-shaped bolt (or press block + bolt) and the two ends of the groove, when the wire rope is subjected to tension, the force is applied to the sensor through the guide rotation. It is suitable for measuring and controlling the tension of wire rope. It is mainly used in lifting equipment such as electric hoist, material hoist and wire rope hoist.

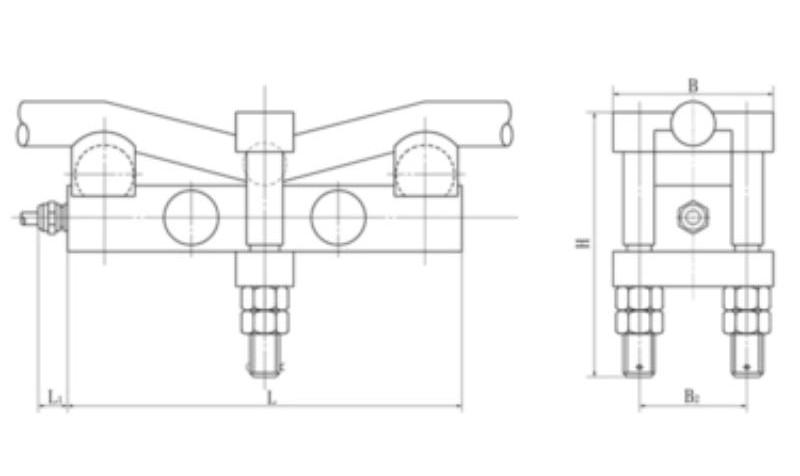

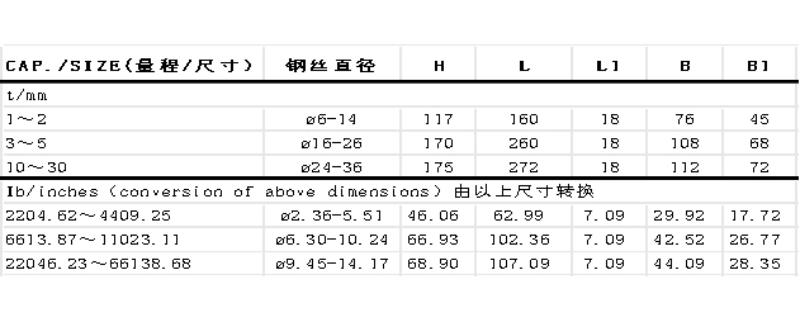

Dimensions:(In mm. 1mm=0.03937 inches)

Structure and materials

Material: Usually made of alloy steel or stainless steel, it has good corrosion resistance and high strength, and can work stably in harsh environments.

Side pressure design: The sensor adopts a side pressure structure, which enables it to accurately sense the force transmitted by the wire rope without directly bearing the tension.

Working principle

Force transmission: The wire rope is fixed to the sensor by U-bolts or pressure blocks. When the wire rope is subjected to tension, the force is transmitted to the sensor through the guide wheel, activating the internal measuring element (such as strain gauge) to convert the mechanical force into an electrical signal.

Signal output: The generated electrical signal can be output in analog or digital mode, which is convenient for connecting to the control system for real-time monitoring and adjustment.

Main functions

Tension monitoring: Real-time monitoring of the tension of the wire rope to ensure that it is within the safe range and prevent overload.

Data feedback: Provide accurate tension data to help operators make decisions and optimize lifting operations.

Application areas

Electric hoist: Used to monitor the tension of the wire rope during lifting to ensure safety.

Material hoist: Ensure that the appropriate tension is maintained during lifting operations to avoid accidents.

Lifting equipment: widely used in various lifting machinery, such as cranes, lifting platforms, etc.

Advantages and characteristics

High precision: can provide accurate tension measurement and improve operation safety.

Durability: sturdy design, adaptable to a variety of harsh working environments, long service life.

Easy to install and maintain: simple structure, easy to integrate into existing systems, easy to maintain.

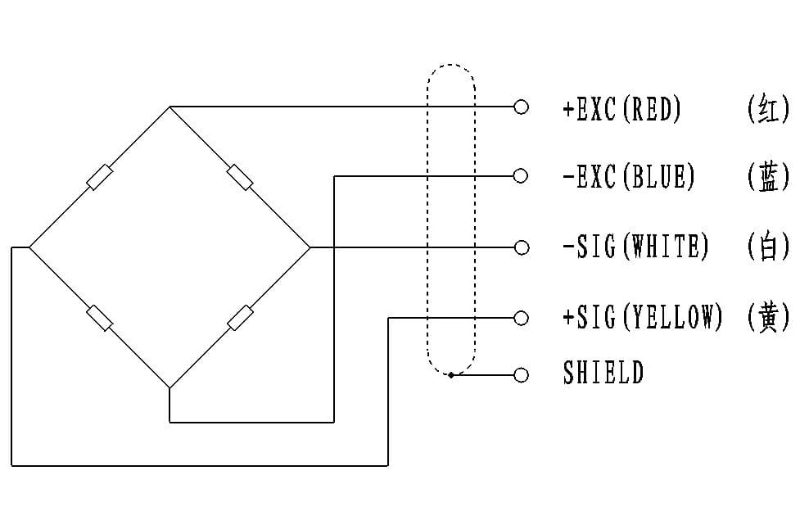

Circuit Diagram:

Red: +input

Blue: -input

White: +output

Yellow: -output

SM40F Side Pressure Load Cell Specification:

| Type | Technical parameters |

| Nominal load range | 1~10t |

| Power supply | 10~12 VDC |

| Zero balance | 1.0±% of rated output |

| Analog output | 2.0±0.01mV/V |

| Input resistance(Rlc) | 400±20Ω(ohms) |

| Output resistance(Ro) | 350±5Ω(ohms) |

| Insulation resistance | ≥5000 MΩ(Mege-Ohms) |

| Class precision | 0.05%FS |

| Effect of temperature | 0.02%FS/10℃ |

| Operating temperature | -40~+85℃ |

| Safe Load Limit | 200% FS |

| Safety margin against yielding | 300% FS |

| Safety margin against breakage | 500% FS |

| Material material | High performance alloy steel or (chromium ratio>15% stainless steel) |

| Protection type | IP67/IP68 |

SM40F Side Pressure Load Cell Applalication:

Lifting equipment

Electric hoist: monitor the tension of the wire rope to prevent overload and improve the safety of operation.

Crane and hoist: ensure that the tension of the wire rope is kept within the safe range during lifting and lifting to avoid equipment damage and safety accidents.

Material handling

Hoist: monitor the tension of the wire rope in real time during the material lifting process to ensure the stability and safety of the lifting.

Conveyor belt system: monitor and control the tension of the wire rope to ensure smooth material transmission.

Construction industry

Tower crane: monitor the tension of the tower crane when lifting heavy objects during construction to ensure structural safety.

Construction hoist: monitor the tension to ensure the safety of workers and materials.

Mining and metallurgy

Mine lifting equipment: monitor the tension in real time during mine lifting and transportation to ensure safe operation.

Smelter: ensure the safety of equipment and personnel during the handling and lifting of heavy objects.

Ship and marine engineering

Anchoring system: monitor the tension of the ship’s anchor chain to ensure anchoring safety.

Offshore platform: Monitor the safety of lifting and handling operations in marine engineering.

Manufacturing

Automated production line: Monitor and control the tension of lifting equipment during the production process to ensure the stability and safety of production.

Scientific research and experiments

Mechanical experiments: Used in laboratories to measure the tension characteristics of materials and structures for related research.

Get In Touch With Us !

Related Products

Related Productspartner

partner

download

download